Easy care green outershell under CDP supply chain

HLGA009B

Composite fabric, Multi-layer construction, High performance to waterproof, water repellent and windproof, TPE Medium moisture permeability membrane

The world's climate change is a serious problem nowadays. We take effective action to join the CDP ( Carbon Disclosure Project) to disclose the environmental data of some of the critical materials. The ecological data helps us understand climate-related risks and enables proactive improvement focusing on production control management. In addition, the data support you in choosing the right manufacturing partner to cope with your climate strategy. Hence, we strive to change the status to become a better supply chain partner.

Our goal is to reduce carbon emissions and maintain a leading competitor. Using fibre elastic strength replace spandex fibre fabrics and TPE membrane is a sustainable choice that benefits the environment, consumers, and businesses.

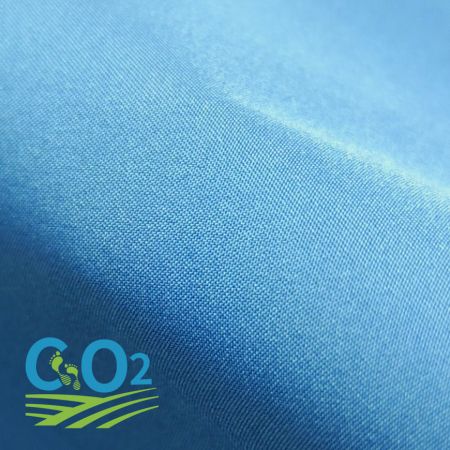

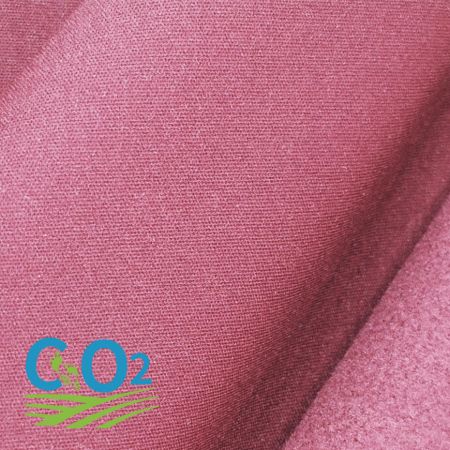

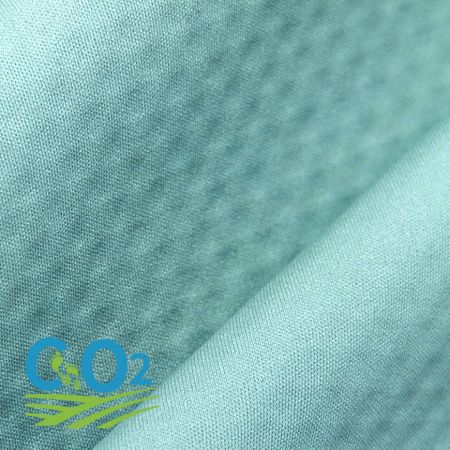

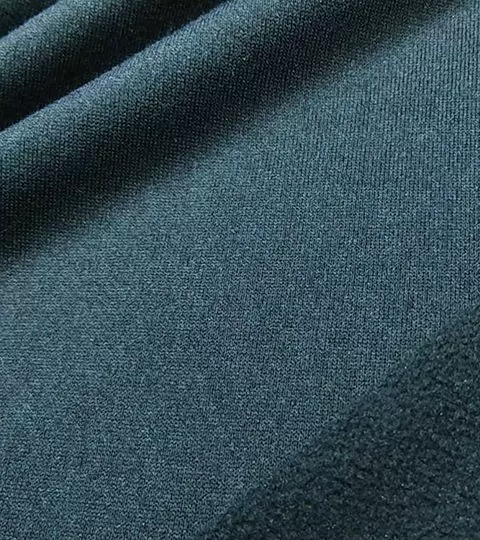

HLGA009B is three layers’ mechanical stretch fabric with excellent performance. In mechanical stretch fabrics, the fibers or yarns used in the fabric are designed to have inherent stretchability. This means that the fabric can stretch and recover without the need for additional elastic components. The stretch properties are engineered into the fabric structure during the manufacturing process..Face side mechanical stretch fabric is made of polyester. Inner side single jersey is made of polyester as well. Membrane in between is TPE.

TPE membrane: A non-porous breathable film with excellent waterproof properties, sweat-wicking, and breathability. It prevents water from penetrating the fabric under a certain pressure while allowing the body's perspiration to pass through the fabric as water vapor, without condensing between the body surface and the fabric. It keeps the wearer dry, warm, resistant to high temperatures, UV-resistant, anti-aging and durable. The composite material exhibits good adhesion, water resistance, breathability, as well as advantages such as abrasion resistance and tear resistance.

Water resistance can reach 10,000 mm (JIS L1092B) and moisture vapor permeability can reach 10,000 g/m² 24 hours (JIS L1099B1).

Features

Water Repellent

90 before wash; 80 after 5 times wash

Waterproof

Test Method JIS L1092B: 10,000 mm

Moisture Vapor Permeability

Test Method JIS L1099B1: 10,000 g/m² 24 hours

-

WATERPROOF fabric

-

WATER-REPELLENT fabric

-

MOISTURE-VAPOR fabric

-

COMPOSITE-MATERIAL fabric

-

BREATHABLE fabric

Specification

- Material: Top fabric: 100% polyester

- Back fabric: 100% polyester

- Weight: 170 g/m2

- Width. 56”

- Finish: Piece dyed fabric and water repellent treatment

- MOQ: 1000YDS

- MCQ: 1000YDS

Application

- hiking

- climbing

- skiing

- cycling

- workwears

- Gallerys

- Download

-

Easy care green outershell under CDP supply chain | Sustainable Fabric - Functional Fabrics Manufacturer | HL

Based in Taiwan since 2000, Hui Liang Industrial Co., Ltd. has been a high functional textile manufacturer. Their main functional fabric products include, Easy care green outershell under CDP supply chain, knitted fabric, woven fabric, water repellent mesh fabric, sustainable and eco-friendly fabric, recycled fabric, single jersey fabric, antimicrobial fabric and sun protective fabric, which are delivered with tests of ASTM, AATCC, JIS and ISO.

Hui Liang is a high technical company which supplies textile material like Hockey equipment, sports gear, apparel, workwear, awnings, shade etc..Develop new environment friendly material is the direction of our innovation center. With more than 20 years experience, HL is specialized in Sustainable Fabric, Functional Fabric, Knit Fabric, Woven Fabric manufacture.

HL has been providing its customers with high performance functional textiles, both with high-quality manufacturing technology, and with 20 years of experience, HL ensures that every customer's needs are met.