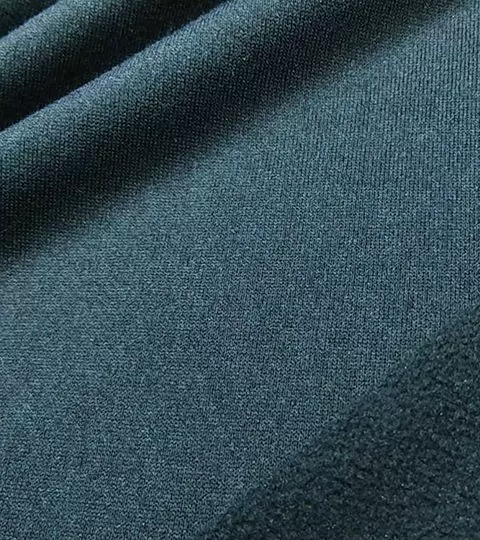

High performance dobby weave fabric

HL17IN0008A

Dobby tech fabric can display a diversity of geometric patterns and use different denier yarns to create texture to the materials.

The functional yarns, weaving know-how and finish treatments are significant elements to convert into technical textile quality. Fabric's durability is determined by its ability to retain its shape even after constant wear and washing. How to identify durable material?

Tensile strength/ Abrasive resistance

The influences of fibre types and fabric constructions determine the fabric's durable ability. There are many functional yarns throughout the market. We are good at interlacing various functional yarns, such as recycled, bio-based, high tensile strength, elastic, water repellent, etc., to create high-performance woven fabrics in textile looms.

Fabric construction can improve abrasive resistance. Dobby weave is a type of weaving technology made with a specialized dobby loom. The technique is designed to raise and lower warp yarns individually, creating a distinctive and geometric pattern in the fabrics. The different thicknesses of threads make the textured surfaces and boost abrasive strengths to withstand friction.

The chemical process is another way to vary textile quality. The standard textiles adopt high-value-added finish treatment options such as PFC-Free, C0, DWR, PU coatings and many more to change the fabric performance.

We have over a hundred patterns and textured fabrics in our library, and we continue bringing the best innovative textiles to meet your need. If you need to know what types of fabric textures and structures are best for your projects, we are here to help. We welcome customized developments to deliver what our customers want most: quick and effective solutions. You can call, email or online chat with us to get help with your needs.

Durability, abrasion resistance, traction, and flexibility make you strong during every adventures.

Features

- full-dull luster nylon 6-two thickness threads-N200D+N800D

- Abrasion and tear resistance

- Water repellent

- Plant and petroleum celluloses combination.

-

Woven-Fabric

-

Water-Repellent-Fabric

-

Anti-abrasive-Prevent outer force to scratch or cut the body

-

The fabric contents non-hazardous materials

Specification

- Width: 58”

- Weight: 290GSM

- Content: 78% Nylon 22% Rayon

- Finish: Water-repellent treatment ( C0)

- and polyurethane coating

Application

- Outdoor garments and footwear

- gloves

- cap/hat

- home décor materials

- backpack

- bike bag fabrics

- Pet accessories

- Download

High performance dobby weave fabric | Sustainable Fabric - Functional Fabrics Manufacturer | HL

Based in Taiwan since 2000, Hui Liang Industrial Co., Ltd. has been a high functional textile manufacturer. Their main functional fabric products include, High performance dobby weave fabric, knitted fabric, woven fabric, water repellent mesh fabric, sustainable and eco-friendly fabric, recycled fabric, single jersey fabric, antimicrobial fabric and sun protective fabric, which are delivered with tests of ASTM, AATCC, JIS and ISO.

Hui Liang is a high technical company which supplies textile material like Hockey equipment, sports gear, apparel, workwear, awnings, shade etc..Develop new environment friendly material is the direction of our innovation center. With more than 20 years experience, HL is specialized in Sustainable Fabric, Functional Fabric, Knit Fabric, Woven Fabric manufacture.

HL has been providing its customers with high performance functional textiles, both with high-quality manufacturing technology, and with 20 years of experience, HL ensures that every customer's needs are met.